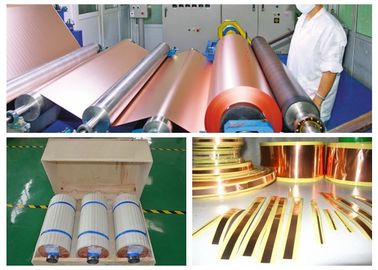

PCB / CCL Copper Foil Sheet , Min 1.20kg / Cm Peel Strength HA Copper Foil

Speficication

Nominal Thickness: 1/2oz

Width: max 1380mm

Cu Content: 99.8%

Tensile Strength: max 280MPA

Elongation: min 4%

Peel Strength: min 1.20kg/cm

Roughness of Shiny side: max 0.4Ra

Roughness of Matte side: max 5~20.0 Rz

High temperature elongation

Standard: IPC 4562

Application: CCL, PCB, EMI Shielding material

Features:

Treated foil in red with High peel strength and Good etch ability,Excellent adhesion to etching resist.

Application:

It is used for Phenolic resin board, Epoxy board

Package:wooden carton

What's our advantages?

Full range of lithium battery materials and equipment:

1).LiFePO4,LiCoO2,LiNiMnCoO2,MCMB,LiMn2O4,Li4Ti5O12,natural graphite,and other electrode

2).Cu&Al&Li foil and Al-Ni tags,Separator

3).Mixer,coater,cutter/slitter,roller,oven,winder,welder,glove box,crimper,tester,and etc. all

4).Full set of production line and technology for lithium ion battery.

Our Competition And Strength:

The real entity factory and trade integration service mode!

More than ten years` history on lithium battery materials and cell products manufacturing!

More than ten years` experience on battery materials and production devices service and exporting!

Using the real projects to demonstate our strength and service!

Typical properties of Standard copper foil for phenolic resin board and epoxy board.

|

Classification

|

Unit |

Requirement |

Test Method |

| Foil Designation |

/ |

T |

H |

M |

1 |

2 |

3 |

IPC-4562A |

| Nominal thickness |

/ |

12um |

1/2 OZ |

3/4 OZ |

1

OZ

|

2

OZ

|

3

OZ

|

IPC-4562A |

| Area Weight |

g/㎡ |

107±4 |

153±5 |

228±8 |

285±10 |

580±15 |

860±20 |

IPC-TM-650

2.2.12.2

|

| Purity |

% |

≥99.8 |

IPC-TM-650

2.3.15

|

| Foil Profile |

Shiny side (Ra) |

սm |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

IPC-TM-650

2.3.17

|

| Matte side(Rz) |

um |

≤6 |

≤8 |

≤10 |

≤10 |

≤15 |

≤20 |

| Tensile Strength |

R.T.(23℃)

|

Mpa |

≥150 |

≥220 |

≥235 |

≥280 |

≥280 |

≥280 |

IPC-TM-650

2.3.18

|

| Elongation |

R.T.(23℃)

|

% |

≥2 |

≥3 |

≥3 |

≥4 |

≥4 |

≥4 |

IPC-TM-650

2.3.18

|

| Subject |

Ω.g/㎡ |

≤0.170 |

≤0.166 |

≤0.162 |

≤0.162 |

≤0.162 |

≤0.162 |

IPC-TM-650

2.5.14

|

| Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.3 |

≥1.6 |

≥1.6 |

≥2.1 |

≥2.1 |

IPC-TM-650

2.4.8

|

| Pinholes&porosity |

Number |

No |

IPC-TM-650

2.1.2

|

| Anti-oxidization |

R.T.(23℃) |

day |

180 |

/ |

| H.T.(200℃) |

Minutes |

60 |

/ |

1. Standard Width,1380(±1)mm,May according to the customer request tailor.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!