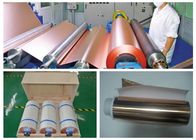

High elongation 0.0105mm (105 um,3 OZ ) single side gray treated RA Copper foil For PCB

Treated with low profile foil in gray.

Quickly details

Area Weight: 890±27g

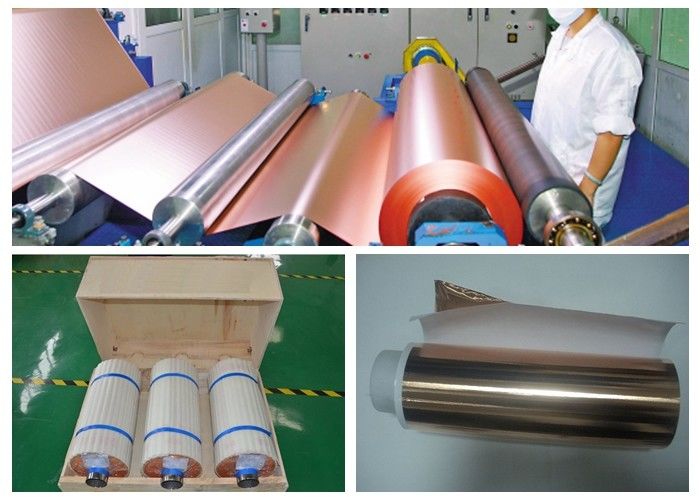

Rolls Width: 5-660 mm

Rolls length: <5000 M

Rolls ID: 76 mm,152 mm

foil Alloy: T2,C11000,C1100,C101,E-Cu58

RollsTemper: H

Features:

1. The treated foil in gray

2. Suitable for Copper Clad Laminate) ,Printed Circuit board

3. Lamellar crystal structure of rolled copper foil leads to high flexibility

Application:

Type CCL (Copper Clad Laminate),PCB(Printed Circuit board)

. Conventional FR-4

· Lead Free Compatible FR-4

· Halogen Free FR-4

· Special Prepreg

· Al-based CCL

FAQ:

Q1: What's your guarantee?

A: All our products have 6 months guarantee after received goods, if any quality problem can contact us.

Q2: What's your delivery time ?

A: The common delivery time is 5-35 working days. The specific delivery time depends on the items and the quantity of your order.

Q3: What's your minimum order quantity?

A: The MOQ is 150 kg.

Q4: Can you supply the sample?

A: We can supply samples with A4 size or rolls of 50 meter.

All size technical sheet for PCB,CCL,Polyimide board,Epoxy board

| Thickness |

0.009-0.09mm |

Width≤520mm |

| Item |

Unit |

Parameter |

| Thickness |

MM |

0.009 |

0.012 |

0.018 |

0.035 |

0.07 |

0.1 |

| Grade |

- |

C1100 |

C1100 |

C1100 |

C1100 |

C1100 |

C1100 |

| Copper content |

% |

≥99.95 |

≥99.95 |

≥99.95 |

≥99.95 |

≥99.95 |

≥99.95 |

| Area Weight |

g/㎡ |

80±2 |

107±4 |

160±5 |

311±10 |

623±19 |

890±27 |

| Roughness |

(RA) |

Um |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

| Tensile Strength(MP) |

State normal |

Mpa |

≥380 |

≥400 |

≥400 |

≥420 |

≥430 |

≥450 |

| State temper (180℃) |

Mpa |

≥160 |

≥160 |

≥160 |

≥170 |

≥180 |

≥190 |

| Elongation(%) |

State normal |

% |

≥0.8 |

≥1.0 |

≥1.2 |

≥1.3 |

≥1.4 |

≥1.5 |

| State temper(180℃) |

% |

≥5 |

≥6 |

≥8 |

≥15 |

≥20 |

≥25 |

| Peel strength |

N/mm |

≥0.8 |

≥1.0 |

≥1.4 |

≥1.5 |

≥1.8 |

≥2.0 |

| High temperature oxidation resistance(180℃ 1hour) |

- |

Qualified |

Qualified |

Qualified |

Qualified |

Qualified |

Qualified |

Remark:Standard Width,520(±1)mm,accept customization.

The testing of peel strength use FR-4(Tg140℃) and FR-4(Tg170℃) prepreg. Foils on different prepreg have different peel strength, you should confirm the peel strength of foils with your prepreg.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!