Matte Side Treatment ED Copper Foil 15um With Low Profile Foil

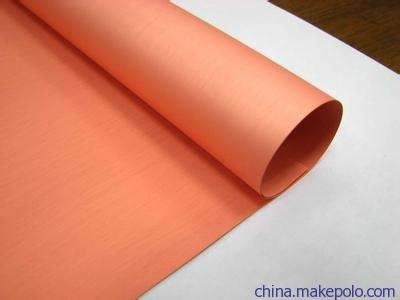

Matte Side Treatment ED Copper Foil Rolled with Low Profile 76mm / 152mm Roll ID

matte side treatment low profile foil in back/red.

Quickly details

Thickness: 0.012-0.070 mm,15um

Width: 5-520 mm

Length: 500-5000 M

ID: 76 mm,152 mm

Alloy: T2,C11000,C1100,C101,E-Cu58

Temper: H

Features:

1. the treated foil in gray or red

2. High profile with properties of LP-S-B/R suitable for FCCL

3. Grain structure of copper foil leads to high flexibility

4. Excellent etching performance

5. low profile enables to make fine circuit pattern

Application:

1. Casting and lamination type FCCL

2. Super fine pattern FPC

3. Chip on flex (COF) for LED

Compare between CA copper foil and ED copper foil

1. Process: rolled copper foil (Rolling process),ED copper foil (Electrodeposition process)

2. Strength toughness: rolled copper foil is a flaky crystalline structure, so the strength and toughness is better than electrolytic copper foil, so most of the rolling copper foil used in flexible printed circuit boards.

3. Width: rolling copper foil width ≤ 620mm, electrolytic copper foil width ≤ 1380mm

4. Density: rolled copper foil higher density, the surface is relatively smooth, conducive to the production of printed circuit board after the rapid transmission of the signal, so high-frequency high-speed transmission, fine lines printed circuit board also used some calendering copper Foil.

5. Surface treatment width:rolled copper foil be limited by Surface treatment widest effective width of 520mm.

Package:wooden carton

FAQ:

Q1: What's your guarantee?

A: All our products have 6 months guarantee after received goods, if any quality problem can contact us.

Q2: What's your delivery time ?

A: The common delivery time is 5-35 working days. The specific delivery time depends on the items and the quantity of your order.

Q3: What's your minimum order quantity?

A: The MOQ is 150 kg.

Q4: Can you supply the sample?

A: We can supply samples to check the quality before bulk order. But the price will be sample price not wholesale price.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q6. what is your standard width?

A: 520mm and 620mm,we accept customization for the width. we can cut it into any size that you demand after pass discussing.

Typical properties of LP-S-B/R ED electrolytic copper foil(for FPC or inner layer of HDI)

|

Classification

|

Unit |

Requirement |

Test Method |

| Foil Designation |

/ |

|

1 |

H |

M |

1 |

IPC-4562A |

| Nominal thickness |

/ |

10um |

12um |

1/2 OZ(18um) |

3/4 OZ(25um) |

1 OZ(35um) |

IPC-4562A |

| Area Weight |

g/㎡ |

98±4 |

107±4 |

153±5 |

228±8 |

285±10 |

IPC-TM-650

2.2.12.2

|

| Purity |

% |

≥99.8 |

IPC-TM-650

2.3.15

|

| Foil Profile |

Shiny side(Ra) |

սm |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

IPC-TM-650

2.3.17

|

| Matte side(Rz) |

um |

≤4.0 |

≤4.5 |

≤5.5 |

≤6.0 |

≤8.0 |

| Tensile Strength |

R.T.(23℃) |

Mpa |

≥260 |

≥260 |

≥280 |

≥280 |

≥280 |

IPC-TM-650

2.3.18

|

| H.T.(180℃) |

Mpa |

≥180 |

≥180 |

≥180 |

≥180 |

≥180 |

| Elongation |

R.T.(23℃) |

% |

≥5 |

≥6 |

≥8 |

≥10 |

≥12 |

IPC-TM-650

2.3.18

|

| H.T.(180℃) |

% |

≥5 |

≥6 |

≥7 |

≥8 |

≥8 |

| Peel Strength(FR-4) |

N/mm |

0.7 |

0.8 |

1.0 |

1.1 |

1.2 |

IPC-TM-650

2.4.8

|

| Ibs/in |

4 |

4.6 |

5.7 |

6.3 |

6.9 |

| Pinholes&porosity |

Number |

No |

IPC-TM-650

2.1.2

|

| Anti-oxidization |

R.T.(23℃) |

180days |

/ |

| H.T.(200℃) |

60 Minutes |

/ |

1. Standard Width 520mm,max width 1295(±1)mm,May according to the customer request tailor.

We test the peel strength with PI ,please reconfirm with your pp.

LP ED Copper Foil Pakcage Photos :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!