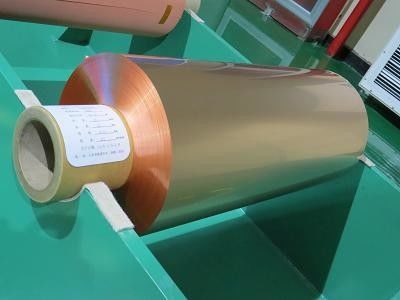

HTE electrodeposited ED electrolytic copper foil(High temperature elongation electrodeposited electrolytic ED Copper foil)

EMI shielding conductive tape is specially designed for packaging cables and RF to prevent EMI crosstalk from wiring harnesses, unique metal processing tape has excellent flexibility of compliance, good tensile strength and adhesion of the adhesive. It can not only meet the requirements of conventional EMI/ESD but also can be professionally applied to cable EMI shielding.

Quickly details of ED Copper Foil:

single side side treatment low profile foil in back/red.

Thickness: 0.012-0.070 mm

Width: 5-520 mm

Length: 500-5000 M

ID: 76 mm,152 mm

purity:99.8%

Features of ED Copper Foil :

1. the treated foil in gray or red

2. High peel strength

3. Good etch ability

4. Excellent adhesion to etching resist

5. Anti foil cracking by high elongation at elevated temperature

6. Eco-friendly products and processes

Application:

1. Polyimide board

2. Epoxy board

Compare between CA copper foil and ED copper foil

1. Process: rolled copper foil (Rolling process),ED copper foil (Electrodeposition process)

2. Strength toughness: rolled copper foil is a flaky crystalline structure, so the strength and toughness is better than electrolytic copper foil, so most of the rolling copper foil used in flexible printed circuit boards.

3. Width: rolling copper foil width ≤ 620mm, electrolytic copper foil width ≤ 1380mm

4. Density: rolled copper foil higher density, the surface is relatively smooth, conducive to the production of printed circuit board after the rapid transmission of the signal, so high-frequency high-speed transmission, fine lines printed circuit board also used some calendering copper Foil.

5. Surface treatment width:rolled copper foil be limited by Surface treatment widest effective width of 520mm.

Package:wooden carton

FAQ:

Q1: What's your guarantee?

A: All our products have 6 months guarantee after received goods, if any quality problem can contact us.

Q2: What's your delivery time ?

A: The common delivery time is 5-35 working days. The specific delivery time depends on the items and the quantity of your order.

Q3: What's your minimum order quantity?

A: The MOQ is 150 kg.

Q4: Can you supply the sample?

A: We can supply samples to check the quality before bulk order. But the price will be sample price not wholesale price.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q6. what is your standard width?

A: 520mm and 620mm,we accept customization for the width. we can cut it into any size that you demand after pass discussing.

Typical properties of High temperature elongation copper foil(for epoxy &polyimide board)

|

Classification

|

Unit |

Requirement |

Test Method |

| Foil Designation |

/ |

T |

H |

M |

1 |

2 |

3 |

IPC-4562A |

| Nominal thickness |

/ |

12um |

1/2 OZ |

3/4 OZ |

1

OZ

|

2

OZ

|

3

OZ

|

IPC-4562A |

| Area Weight |

g/㎡ |

107±4 |

153±5 |

228±8 |

285±10 |

580±15 |

860±20 |

IPC-TM-650

2.2.12.2

|

| Purity |

% |

≥99.8 |

IPC-TM-650

2.3.15

|

| Foil Profile |

Shiny side (Ra) |

սm |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

IPC-TM-650

2.3.17

|

| Matte side(Rz) |

um |

≤5 |

≤7 |

≤8 |

≤9 |

≤13 |

≤18 |

| Tensile Strength |

R.T.(23℃)

|

Mpa |

≥150 |

≥220 |

≥235 |

≥280 |

≥280 |

≥280 |

IPC-TM-650

2.3.18

|

| Elongation |

R.T.(23℃)

|

% |

≥4 |

≥4 |

≥4 |

≥5 |

≥5 |

≥5 |

IPC-TM-650

2.3.18

|

| Subject |

Ω.g/㎡ |

≤0.170 |

≤0.166 |

≤0.162 |

≤0.162 |

≤0.162 |

≤0.162 |

IPC-TM-650

2.5.14

|

| Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.3 |

≥1.6 |

≥1.6 |

≥2.1 |

≥2.1 |

IPC-TM-650

2.4.8

|

| Pinholes&porosity |

Number |

No |

IPC-TM-650

2.1.2

|

| Anti-oxidization |

R.T.(23℃) |

day |

180 |

/ |

| H.T.(200℃) |

Minutes |

60 |

/ |

3. Standard Width,1295(±1)mm,May according to the customer request tailor.

We test the peel strength with FR-4(Tg140) prepreg ,please reconfirm with your pp.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!