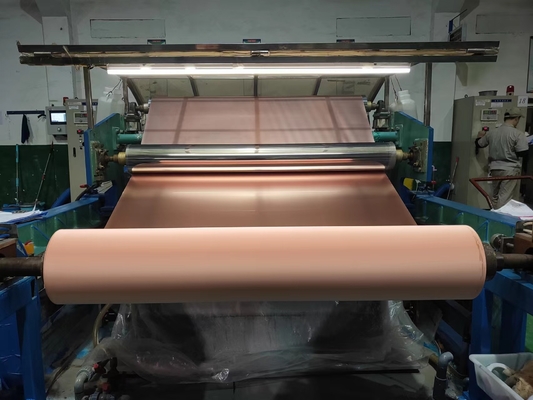

CEM-1 Jumbo coil high temperature elongation 3 oz ED electrodeposited copper foil for PCB

Specifications:

1. single side side treatment low profile foil in back/red.

2. T: 0.105mm,105 um,105 mic

3. Width: 5-1380mm.

4. Max width :1380mm.

5. Standard width :1290mm.

CA copper foil and ED copper foil introduction

1. Width: rolling copper foil width ≤ 620mm, electrolytic copper foil width ≤ 1380mm

2. Density: rolled copper foil higher density, the surface is relatively smooth, conducive to the production of printed circuit board after the rapid transmission of the signal, so high-frequency high-speed transmission, fine lines printed circuit board also used some calendering copper Foil.

3. Surface treatment width:rolled copper foil be limited by Surface treatment widest effective width of 520mm.

FAQ:

Q13. Can we come to China visit factory ?

Yes ,you can .

Q14. Can you cut into small size?

Yes, we can.

Q15.is the copper foil Floating in box?

Yes, it is .

Detail Description:

1. the treated foil in gray or red.

2. High peel strength.

3. Good etch ability.

4. Excellent adhesion to etching resist.

5. Anti foil cracking by high elongation at elevated temperature.

6. Eco-friendly products and processes.

what's Application:

1.PCB and antenna PCB .

2.PCB manufacture .

HTE ED copper foil for pcb(high elongation copper foil at high temperature)

| Thickness |

um |

9 |

12 |

18 |

25 |

35 |

70 |

IPC 4562

4.6.3.1

|

| Area weight |

g/m² |

80±1 |

107±3 |

153± |

215±5 |

285±5 |

585±8 |

IPC 4562

4.6.3.2

|

| Roughness |

(RA) |

μm |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

IPC 4562

4.6.9

|

| (RZ) |

μm |

<6.0 |

<6.5 |

<8.0 |

<9.0 |

≤10.0 |

<15 |

|

Copper≧

|

% |

99.8 |

IPC 4562

4.6.3.1

|

| Tensile Strength |

state normal |

Mpa |

>300 |

>300 |

>300 |

>300 |

>300 |

>280 |

IPC 4562

4.6.4

|

| state temper (180℃) |

Mpa |

>15.0 |

>18.0 |

>18.0 |

>18.0 |

>18.0 |

>18.0 |

| ElongationI |

state normal |

% |

>3.0 |

>3.0 |

>5.0 |

>6.0 |

>10.0 |

>10.0 |

IPC 4562

3.5.3

|

| state temper (180℃) |

% |

>2.0 |

>2.5 |

>2.5 |

>3.0 |

>5.0 |

>5.0 |

| Peel strength |

N/mm |

>1.0 |

>1.05 |

>1.35 |

>1.70 |

>1.8 |

>2.0 |

IPC 4562

4.6.7

|

|

High temperature oxidation resistance(200℃,

40min)

|

No color change |

Standard |

| Solderability |

Good |

Standard |

| Solderability |

Good |

IPC 4562

4.6.12

|

Standard Width,1380(±1)mm,May according to the customer request tailor. We test the peel strength with FR-4(Tg140) prepreg ,please reconfirm with your pp.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!